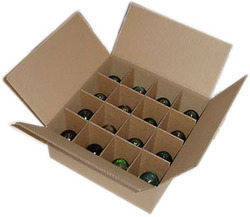

Slotted Boxes

Slotted-type Boxes consist of basically one piece with a stitched, taped or glued manufacturer's joint and top and bottom flaps. They are shipped flat, ready to use and require closing using the flaps provided. There are many types of slotted boxes

Regular Slotted Container: All flaps have the same length, and the two outer flaps (normally the lengthwise flaps) are one-half the container's width, so that they meet at the center of the box when folded. If the product requires a flat, even bottom surface, or the protection of two full layers, a fill-in pad can be placed between the two inner flaps. This is a highly efficient design for many applications. There is very little manufacturing waste. The RSC can be used for most products and is the most common box style.

Overlap Slotted Container (OSC) All flaps have the same length. The outer flaps overlap by one inch or more. The box is easily closed, usually with staples driven through the overlap area. This style is used when the length of the box is considerably greater than the width, resulting in a long gap between the inner flaps. The sealed overlap helps to keep the outer flaps from pulling apart.

Full Overlap Slotted Container (FOL) : All flaps have the same length (the width of the box). When closed, the outer flaps come within one inch of complete overlap. The style is especially resistant to rough handling. Stacked on its bottom panel, the overlapping flaps provide added cushioning. Stacked on its side, the extra thickness provides added stacking strength.